Cooling warehouses at the best of times is a challenge. Tightly packed with racking and products, achieving consistent temperatures throughout is a major concern, as is, having the cooling capacity to maintain conditions in extreme circumstances.

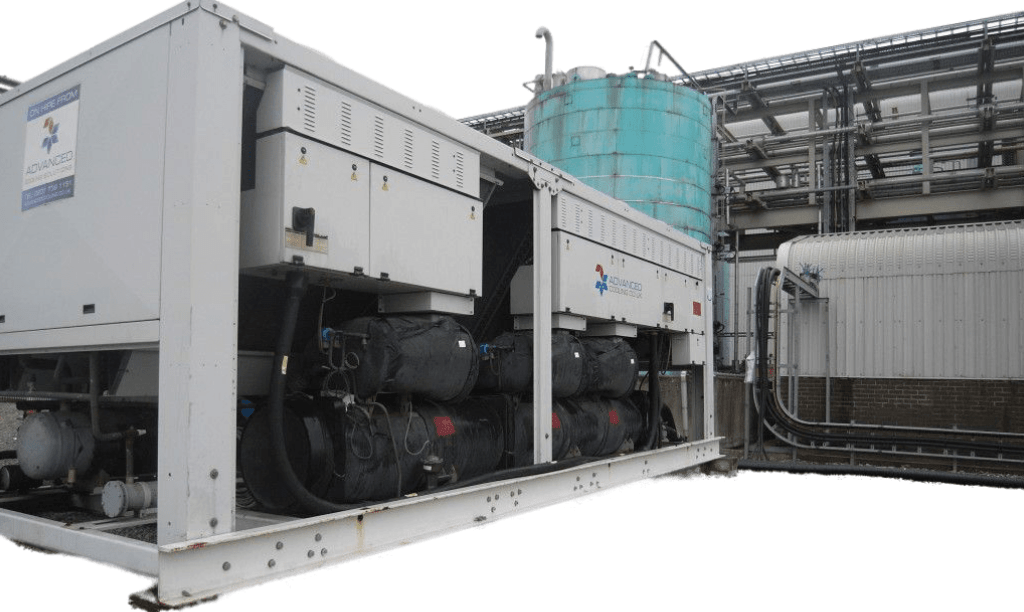

Sometimes using temporary systems can be a good way to correct problem areas. Portable equipment can be installed at short notice and has been found to provide good solutions. These portable temporary systems can be hired on contracted terms to suit the business’s operational needs, and can include amongst others, water chillers and multiple air handling systems for larger scale projects.

Fast procurement of equipment in response to problems.

Flexible hire terms- equipment can be kept for as long as is required. Rental systems can be added to or adjusted as required.

Limit capital expenditure- No upfront capital cost for equipment, leaving additional funds for core business activities.

A full turnkey solution- Specialist companies will design, install and maintain all plant in good condition.