If you’re wanting to purchase or hire a chiller unit, or want to know what types of chillers are on the available, this blog will discuss the different types of chiller units. Please note that this post is focused on water cooling machines.

There are a many different types of chiller units on the market, so it’s essential to know your options. Each chiller serves similar but different functions, so knowing their purposes can help you decide which one will best suit you. But what are the different types of chillers?

Here are some of the different types of chiller units:

Chiller units are a must for most businesses. Large businesses operations can generate a lot of heat during their operations. This is especially true in the modern would of data centres and other computer heavy industries. Keep reading to learn more about the different types of chiller units!

Whilst different types of chillers may perform a multitude of functions, the basic principles of the refrigeration cycle remain the same. Essentially, by using vapour compression in a circular system you are moving energy form one place to another. The application of the machine may change and this will determine the type required, but the basic physics remain the same.

There are many types of chiller units on the market, it can be tricky to distinguish which would be right for you or your business or process. Below are some of the generally available and commonly used chillers.

This type of chiller is known as a hybrid chiller because it combines some of the functions of different cooling methodologies. The most common being evaporative condensing and integral free cooling dry air coils. Hybrid chillers if applied correctly can offer significant energy savings.

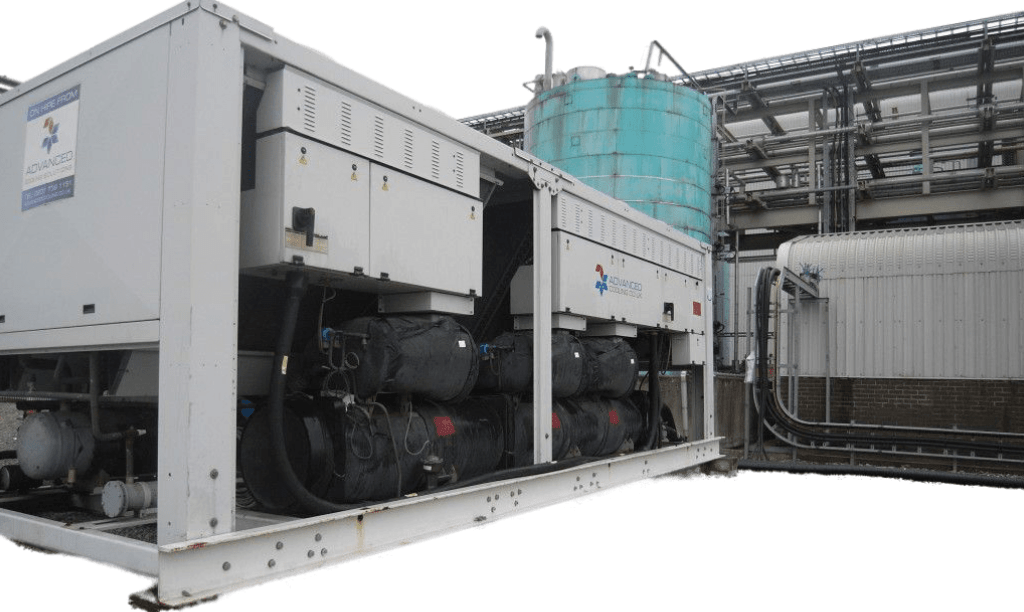

Without doubt, the common type of machine in operation is the air cooled water chiller. These machines remove energy (chill) from water using a vapour compression system that includes a compressor, evaporator and dry air cooler. In simple terms the machine takes the energy from the water, moves it through the machine and discharges it from the fans. Generally utilised in larger offices and production processes.

Water cooled chillers operate in a very similar way to air cooled chillers. However, instead of using fans and a dry cooler to discharge the heat from the chilled water, they use water as the heat rejection medium. Water cooled machines use a heat exchanger to transfer the heat into a water loop. In turn this loop is passed through another, generally remote, heat exchanger to atmosphere. Water cooled chillers are usually used on larger buildings or industrial processes requiring large capacity cooling.

Heat recovery chillers are incredibly versatile, They can simultaneously produce both hot and cold water for different operations. These machines recover some of the energy that would have otherwise been rejected into heating applications. This obviously means that they provide more efficient operation of a building. Heat pumps or reverse cycle, are chillers that can produce either warm or chilled water in the water loop.

More often than not these chillers offer very large capacity cooling. Usually water cooled, they are used in large buildings and district cooling systems. The main differences to air cooled chillers is the compression method and evaporator configuration. As the name implies, a centrifugal, commonly known as a turbo, compressor is used for vapour compression. Flooded evaporators are predominantly used. Long lived, and found in dark basements, many of these machines are in operation decades after installation

Although chillers are typically used in industrial spaces, there’s no denying that they’re effective and nifty no matter where they’re used. The range of chillers available allows for versatility and the freedom to determine which one will work best for you. Some benefits of chillers include:

Chillers are eco-friendly. Air cooled chillers do not require the use of large amounts of water for the cooling process.

Chillers are effective. Chiller units provide very efficient use of space. They offer very powerful performance against space used.

A chiller can boost productivity. In industrial spaces that use heavy-duty equipment prone to overheating, a chiller can cut down the time needed for the equipment to cool down, allowing for more productivity. Similarly, They can cool workspaces, boosting the performance of personnel.

Water chillers popularity speaks volumes about their enduring usefulness. When applied in the correct way they are efficient and reliable workhorses that bring massive benefits.