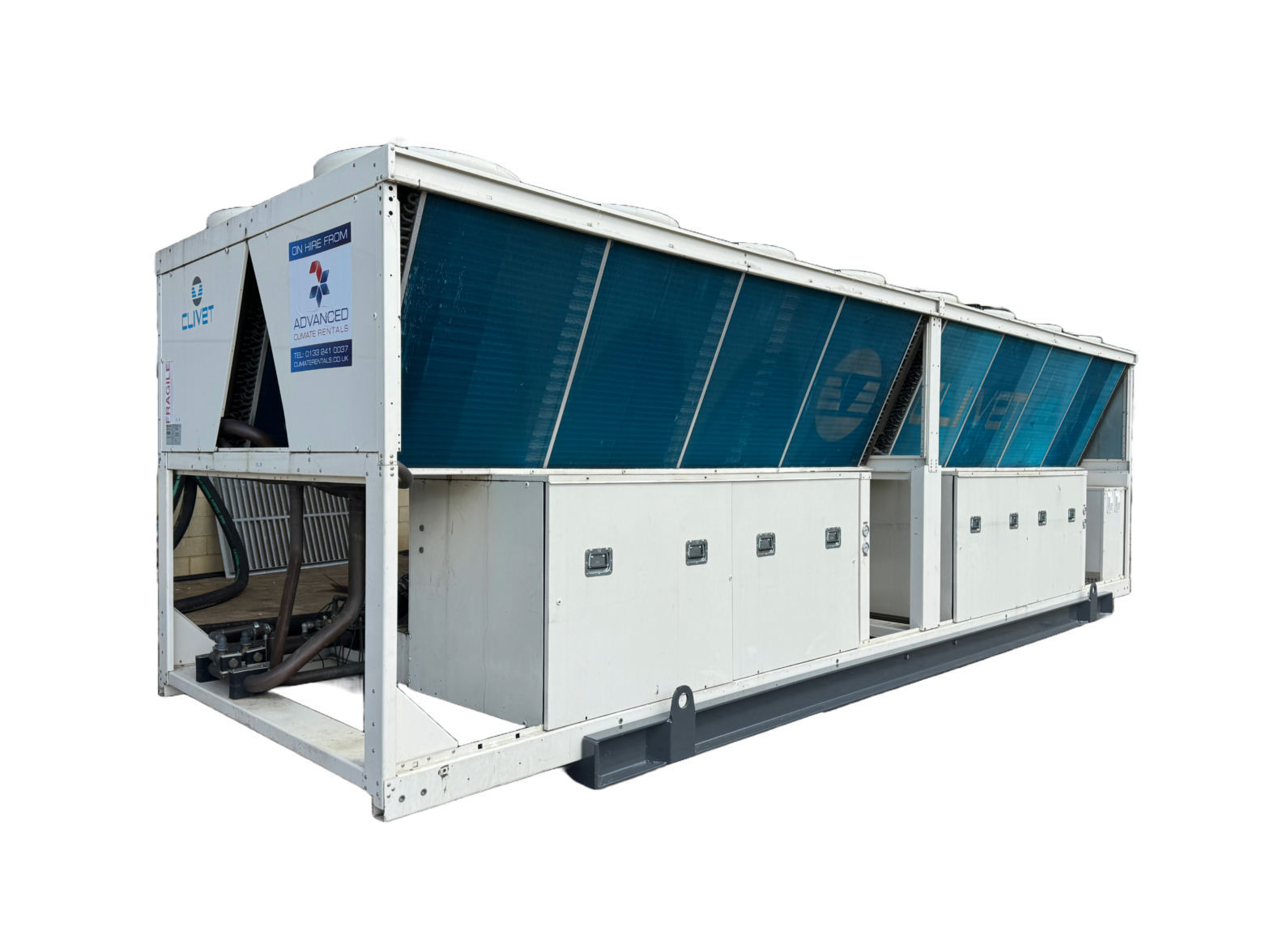

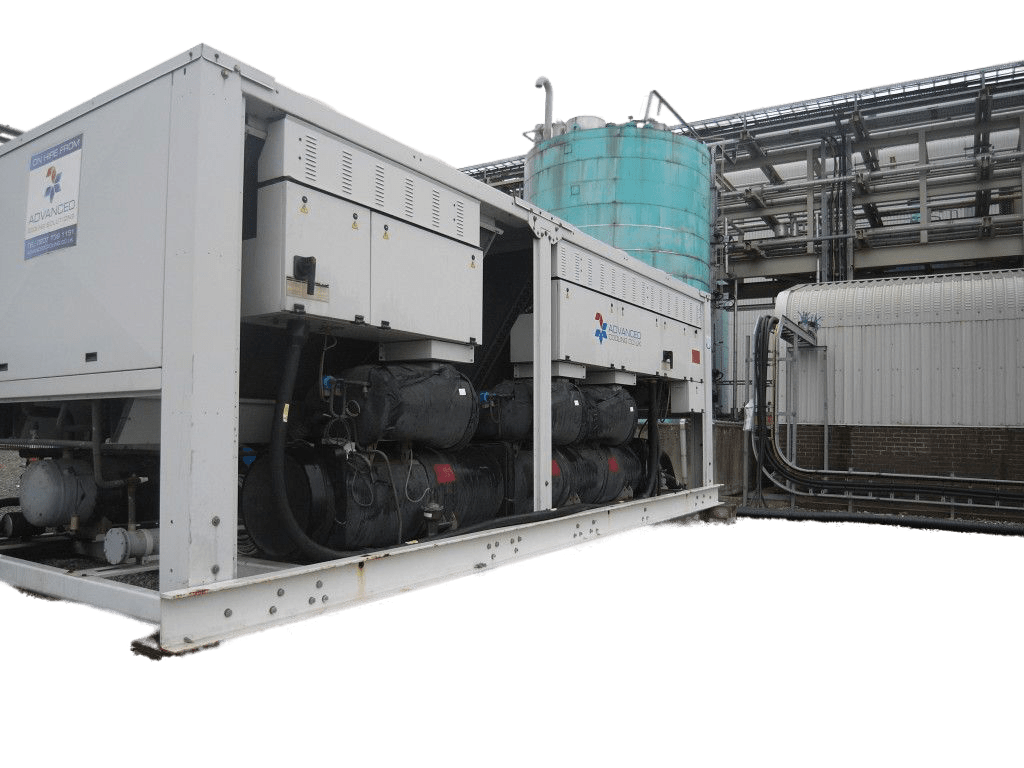

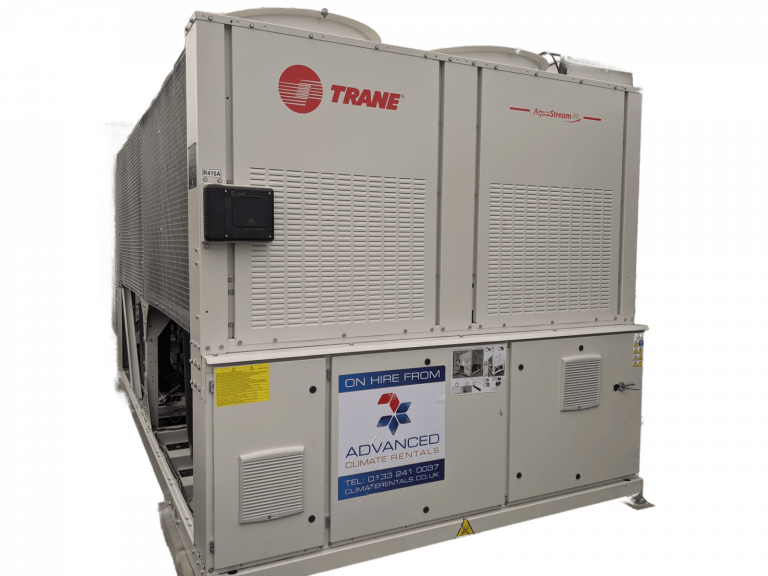

Temporary chiller hire is a service supplying portable machines that can be delivered to a site and set-up quickly using modular hosing and cabling. As a result, losses from downtime can be limited. Flexible chiller hire leasing terms are very good options for businesses with an eye on capital spend and fast growth.

How Can Acr Help Your Business?

At ACR we focus on design, convenience and price to get things done professionally with minimal fuss.

Furthermore, our diversified fleet of chiller rental are fully backed by 24/7 engineering support. Consequently, your chiller rental will be properly designed, installed and supported at all times. Great for business and reduced stress levels!

We have a wealth of engineering experience in the supply of temporary chillers. Our modern fleet of chiller hire is available in capacities from 20- 1000kw. All are available with hose and cable from stock for fast delivery.