Chilled logistics plays a crucial role in ensuring consumables stay fresh. However, what exactly is chilled logistics?

Chilled logistics is the transportation of temperature-sensitive food and beverages that could be spoiled by incorrect conditions. Chilled logistics is essential for health and safety and ensuring produce stays in prime condition.

Chilled logistics form part of what is called the Cold Chain. The Cold Chain, as its name alludes too, is the maintaining of a product at optimal conditions from production to consumer. Without cold chain logistics, it’s likely that most of the food and beverages you purchase at stores would be spoiled. Keep reading to learn more about cold chain logistics and its benefits!

Cold chain logistics isn’t only subject to perishables such as food and beverages. Chilled logistics is also applied to things such as pharmaceuticals that could falter under incorrect conditions, like vaccines.

By implementing chilled logistics in goods transportation and packaging, the transportation company and manufacturer can ensure that goods are fit for consumption and don’t spoil before the expiration date. This massively reduces waste.

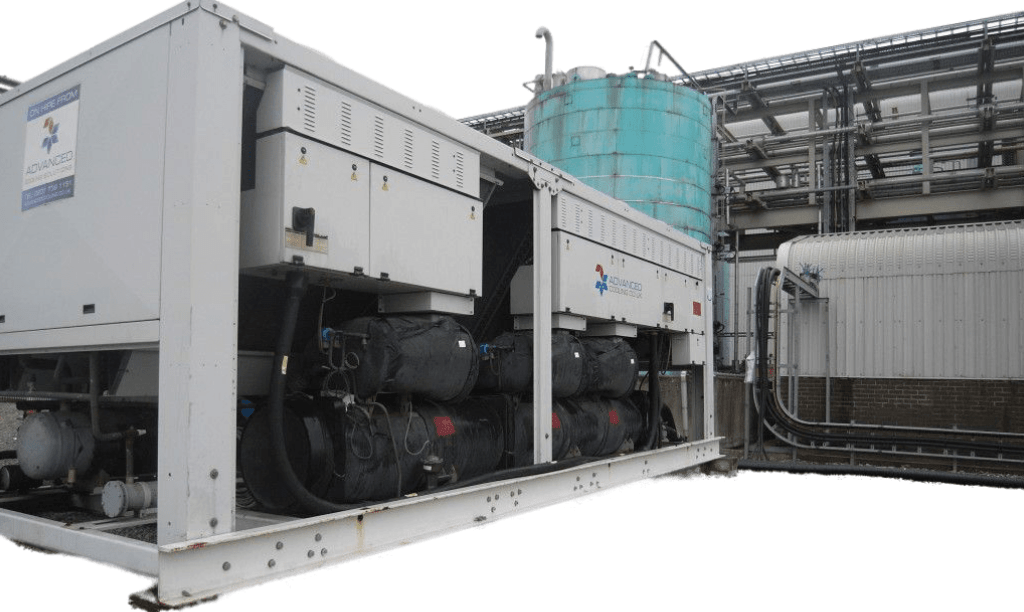

Relevant packaging methods refer to the packaging and transportation methods that will be conducive to the goods’ longevity and freshness. For example, specific meats and seafood would require refrigerated transportation and packaging to remain unspoiled.

Incorrect packaging and unreliable chilled logistics can cause the perishables to spoil long before their stipulated expiration date. Cold chain logistics is incredibly important, as it requires a thorough understanding of the goods’ chemical processes to ensure their transportation methods are appropriate and provide protection against being prematurely spoiled.

Chilled logistics provide a handful of benefits that not many people are aware of. Without Cold Chain logistics, it would be unlikely that the perishables we buy are fresh and fit for consumption! Critically, with higher waste comes higher costs for the consumer and/ or products are preserved in a different way with possible detrimental effects on nutrient levels. Or possibly, the range of fresh products available would be greatly reduced.

Not only does chilled logistics prevent the risk of spoiled goods, but it also ensures that cross-contamination doesn’t occur. With proper packaging and transportation, it reduces the risk of diseases spreading and causing you to fall ill.

Cold chain logistics doesn’t only guarantee that food and beverages don’t spoil but also plays a critical part in making sure potential diseases are contained.

Quality control is one of the primary functions of cold chain logistics. Quality control is essential for health and safety purposes, and it ensures that food and beverages on the shelves are safe for us to consume.

Food wastage is already a rising problem and cold chain logistics aids greatly in preventing the problem from worsening. If the food, beverages, pharmaceuticals, etc. happen to spoil while in transit, the company will have no choice but to dispose of them because they can’t be consumed.

Effective chilled logistics reduces the risk of having to dispose of the items, as goods that were packaged and transported properly won’t have to be thrown away!

Every economic process is ultimately symbiotic if done correctly, as every party will benefit from successful operations. By having a store provide high-quality goods to their customers, the store will make a profit, the customers will leave satisfied, and won’t have their health compromised by goods that were incorrectly stored and transported!

Chilled logistics is a pivotal economic process, as it lays part of the foundation that delivers to us the best quality goods!