Indeed, this project was a real challenge in the purest sense. The client required a cooling system to maintain 8 isles of its warehouse for storage of temperature critical product, including chocolate and creamed coconut.

With summer temperatures in excess of 23 degrees the stored chocolate was beginning to bloom- fat bloom appears as a whitish coating on the surface- obviously not desirable for the consumer.

In addition, creamed coconut squares were starting to melt with oil dripping from packaging. All in all, the client was under extreme pressure to manage the situation to minimise losses of product and maintain contractual obligations.

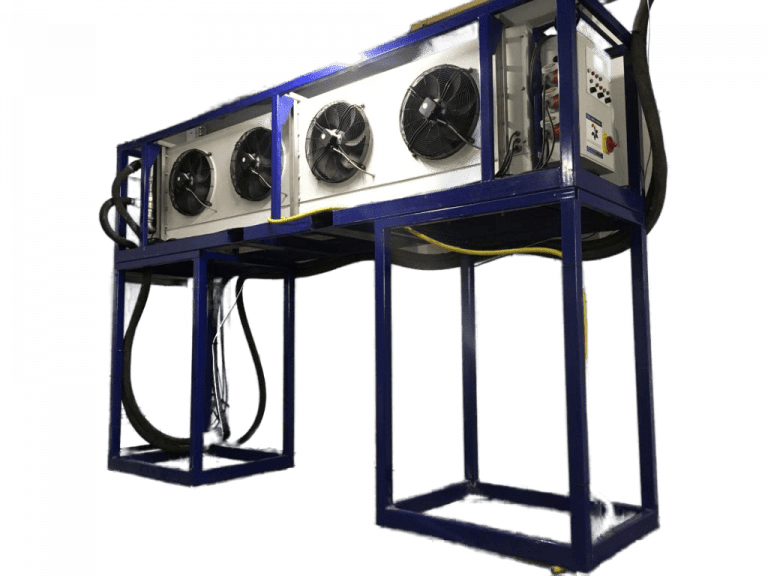

Our first impressions of this project were centred around space issues. As well as restricted floor space, narrow isles and tall racking meant that effective cooling would only be feasible from high level units.

In the past another contractor had positioned AHU’s externally, brutally cutting large holes in the buildings structure to pass ducting through. The overall results were not effective. Air flow/ cooling capacity were not adequate and reinstating the buildings fabric expensive. Overall, a disappointment and a a situation we were determined to avoid for this temporary cooling for chocolate storage project.