If you’re having issues with an overheating warehouse, you’ll likely benefit from warehouse cooling hire. Never heard of it before? Don’t worry. We’ll talk you through what’s involved and what you can expect.

Warehouse cooling can take various forms depending on the issue at hand since there are multiple approaches to cooling a hot space.

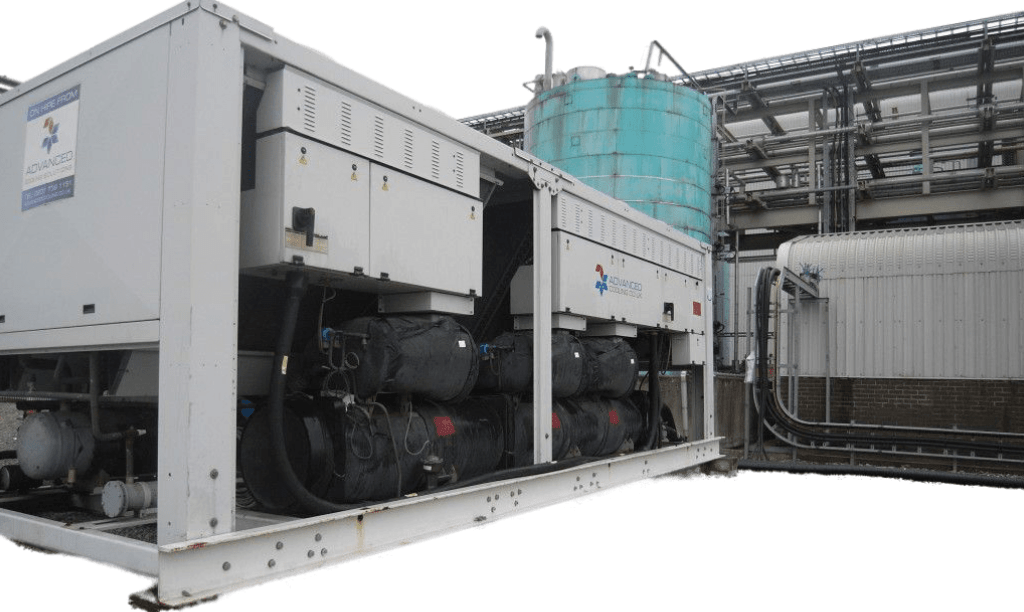

One scenario involves providing temporary cooling in the form of chiller units, which remove heat from the environment, resulting in a cooler and more comfortable space all around. Another option for warehouse cooling is converting to temporary chilled storage or even holding warehouses that house chilled products within certain temperature bands.

Coldstore buildings and areas can be another alternative. These spaces provide a turnkey solution by quickly installing a designated area that’s kept at a certain low temperature to ensure perishable goods don’t perish. Warehouse cooling techniques can be long-term or temporary, so if you only experience these issues in the warmer months, consider working with a warehouse cooling expert only seasonally.

As well as the more typical warehouse cooling techniques, you can think a little outside the box (or the warehouse, should we say) to ensure your chilled goods stay chilled.

Existing warehouses can be partitioned into regular and chilled spaces, or you could erect a new building altogether with temporary building hire. A temporary building could be a designated chilled zone where you’d store your goods, using specialist insulation techniques or other features to ensure a constant chilled temperature.

If you’re using a warehouse to store goods that need to be kept – or at least benefit from being kept – at low temperatures, you’ll need warehouse cooling if your current solutions aren’t working.

You might have noticed that your warehouse feels particularly warm in summer, which points to the need for temporary cooling. Year-round high temperatures may mean some longer-term configurations are necessary.

While you might not necessarily feel the warm temperatures while you’re inside the warehouse, issues might show up in the quality of your goods. Goods that are going off quicker than they should be or machinery regularly showing faults can point to an overheating problem.

If your products need to be kept at an exact temperature, use thermostats to capture the temperature inside the warehouse and compare it to your goal temperature.